This morning when I went to switch on my computer monitor it was completely dead! the display which is a "LG FLATRON W2052TQ" was bought probably around 6 years ago.

So the first thing I did was tested the socket end for a mains voltage, this was fine - so I disconnected all the cables and spent a few minutes doing some web searches; these turned up a common fault with the capacitors in the power supply.

Next I dismantled the monitor; so - out came the bezel; then a few little connectors and a flat-flex cable; then 4 screws and then I had complete access to the power supply.

I could see 2 swollen capacitors and another one which was suspect; so I decided to replace 4 just to be sure; next using solder-wick dipped in flux I removed the old ones cleanly, and then in went the new ones.

After a little struggle to get it all back together I switched it on and it powered up and worked fine.

It seems crappy that this monitor had it's power caps fail after just a few years for the sake of not spending a tiny bit more money on better parts.

Wouldn't power-up, no signs of life!

The power board

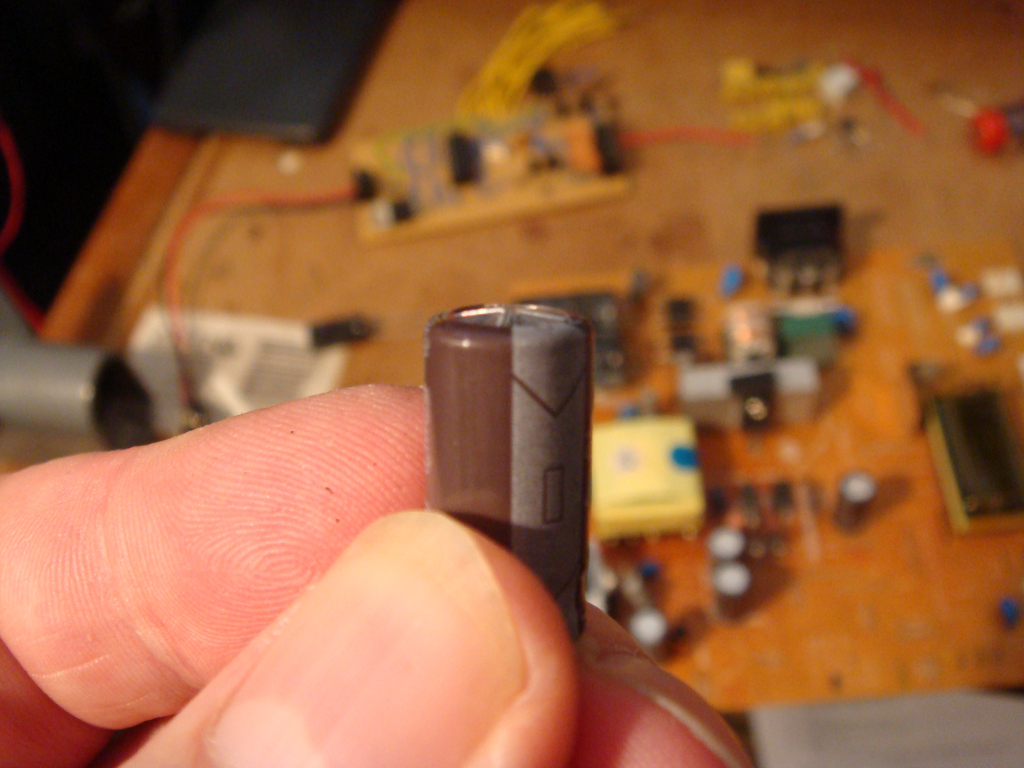

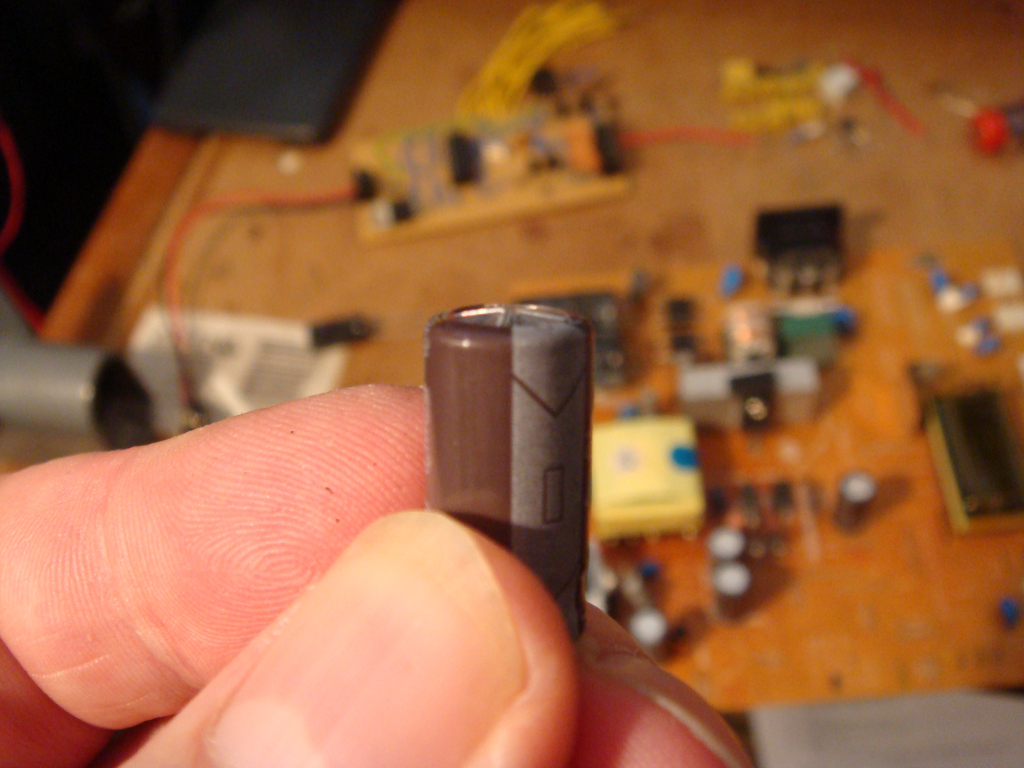

One of the swollen capacitors.

Removed 4; replaced 2 of 4

Replaced 4 of 4. (as seen in the 2x2 arrangement)

Now works a treat!

STOP THE BUS!!

Well, it seems after I replaced the 4 duff caps it worked fine for good while but then I got some screen flicker and hiss; so I cracked it open yet again and replaced another duff cap which appeared to have a very visible bulging of the top.

Not sure how long this display will last as there is some very noticeable heat discolouration of the underside PCB board under what looks to be the backlight inverter.

I'll probably soak test the display for a good few hours and see if anything else fails; but one thing is for sure, I'm not holding my breath for this one!

[UPDATE]

After a few days the unit died yet again!! I think possibly the inverter transformer had given up; so i looked for a replacement board but I couldn't find one, so I dumped the monitor and bought a HP one instead.